The RPS-3 welding parameter recorder is used for moni-toring and recording welding parameters of MMA, MIG/MAG, TIG or SAW welding.

The RPS-3 recorder does not require additional external sensors to monitor basic parameters. Data is gathered directly from the welding machine control and measure-ments circuits via the avaiable communication interface (CAN, RS-232, RS-422/485).

The parameters monitored and recorded in standard are:

- welding current,

- electric arc Voltage,

- electrode wire feed speed,

- shielding-gas volume flow.

Additionally the recorder can be used to record other data sent via the communication interface.

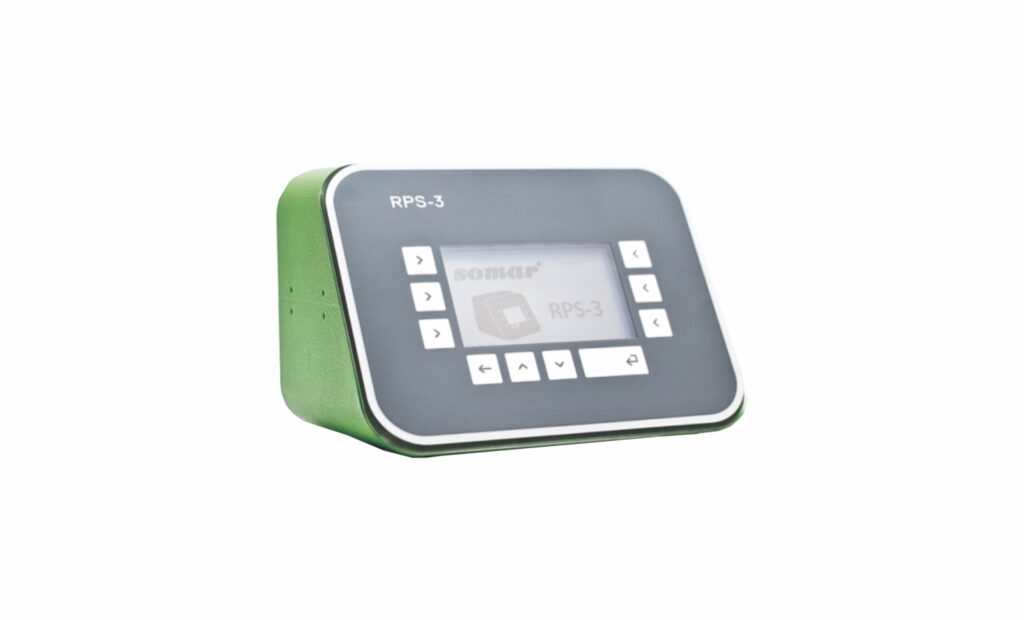

The recorder is equipped with an LCD display, comfor-table user interface and a built-in RFID card reader for identification of users with different level privileges.

It is possible to connect additional devices to the recor-der such as a bar-code reader for entering order num-bers, WPS documents, type of welding materials used etc.

PC software named RPS-Reader 3 was designed for work with the RPS-3 recorder. Data is transferred from recor-der to PC workstation „in-line” via Ethernet (optionally WIFI), or manually using removable USB flash drives.

The recorder is powered directly from the welding magine or external power supply. It is mounted on the welding machine using a special handle.

The most important features of the product:

- welding parameter recorder – data hub

- power supply and data directly from welding machine interface

- mounted on or near welding machine